Back in my undergraduate days we learned about Iron Age torcs. They were massive golden things, symbols of power and prestige. What exactly that power was, we didn’t know. They were made, used, and buried in the ground by people who had no written record. Our assumptions about power rested mainly in our own sets of values. But they are gold, valuable, and precious. Then there are other things that are just as valuable and precious, but more intangible…

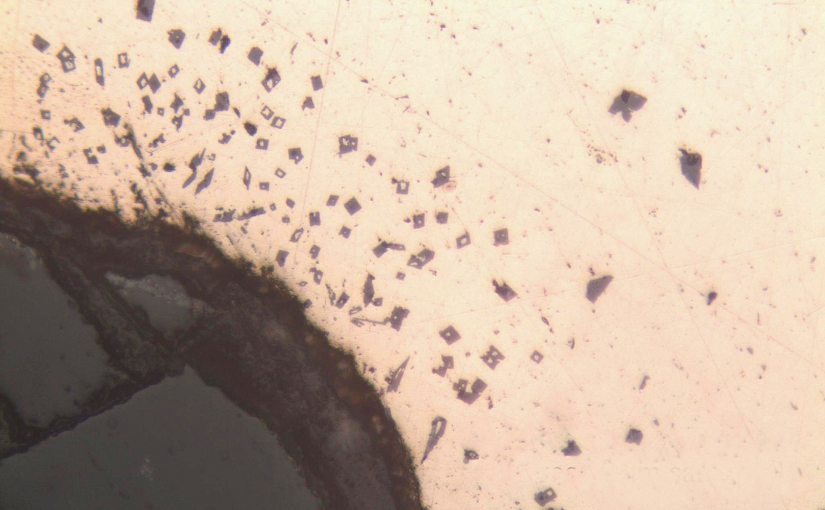

A few years ago Tess Machling contacted me. She knew me as a jeweler/metalsmith turned archaeologist who had a passion for hammers and manufacturing processes. She had some photos and asked me what I thought. No details, just a question about what technique I would use to make something, or what would have caused this sort of mark. I enjoyed the puzzles. I told her how one photo was of metal that had been cracked because the smith had hammered it too much and the metal was fatigued. Could it the result of casting? No, the edges were too sharp, a casting flaw wouldn’t have a crack formed like that. In a few days I’d learn that other metalsmiths she asked told her the same things. She and Roland Williamson, a metalsmith with a background in making museum replicas, were searching for answers, and questioned everyone they could contact. Eventually I learned that we were corresponding about Iron Age gold torcs. The questions she asked us were set up like a blind test to avoid any bias. It was accepted knowledge that torcs were cast in gold and in the course of her research she was coming to the realization that the accepted knowledge was wrong.

The problems with institutions is that they lumber along and have difficulty changing. Even if they want to change, it occurs slowly. Most of the torcs were excavated and interpreted by antiquarians and archaeologists who never worked with metal and never thought to talk to someone who did. In my own research, time and again I came across ‘facts’ that had been passed along from one publication down the line that were just plain wrong. Tess and I both knew what she was up against. The entrenched ideas of institutions and people who uphold them are just as precious as gold. To have these ideas questioned seemed as great as affront as taking the One Ring from Gollum and declaring that it would be thrown into the fires of Mount Doom. But sometimes ideas do need to be cast away. Not randomly, but through careful research, examination, experimentation, and always questioning. I know that early on Tess did have doubts, but she and Roland had so much hard evidence that it was impossible to accept the status quo. Their hard work is changing the way we understand how Iron Age torcs were made. By examining tool marks they are identifying different techniques and seeing the smiths’ hands at work. They have found repairs, retrofits, and an entire catalogue of metalworking tricks of the trade.

In the course of their work, they have published articles in the The Proceedings of the Prehistoric Society, The Journal of the Historical Metallurgy Society, and the Later Prehistoric Finds Group Newsletter. But research is never static, it is something that is forever evolving and growing. As we all learned through this process, entrenched knowledge is terribly difficult to dislodge, even when it’s been proven wrong. There is also a need for transparency in research, and a way for the public to learn and participate in the process, free from paywalls. By producing their new website and blog, The Big Book of Torcs, Tess Machling and Roland Williamson are presenting their work for everyone to read, and question. It’s a wonderfully informative publication with a good bit of humour that will be useful for both the layperson and the academic, not to mention aspiring metalworkers!

Tag: archaeometallurgy

Stories from Times and Epochs, Moscow

I have a Patreon page where I post stories about my travels and experiences casting bronze around the world. Last year I was in Moscow for the Times and Epochs festival, casting bronze with local reenactors. I learned a lot, both about different ways to cast bronze, and also about Moscow and Russia. The story is being told in installments. The first two can be found here:

If you’re interested in reading more, there are both public posts and ones that are available to my Patreon subscribers. There are also other benefits for supporters, including copies of powerpoints and articles, or even postcards sent from wherever I travel. Check and out my Patreon page here and consider a small contribution to support my ongoing work in experimental archaeology.

Vounous Symposium 2019

The 3rd Vounous Symposium went wonderfully well. We experimented with creating faience, including making it from locally resourced materials, resulting in what was named Vounous Blue. This year we had three furnaces, my little pit furnace from last year, one that is self drafting and one short shaft furnace. The self drafting one was used for the faience and small projects. It didn’t get quite hot enough for some things we needed, but the design was a work in progress. The shaft furnace was supposed to be for smelting ore. We had a couple of nice samples, but when we went to collect more, we found that the site was under water. Local members of Vounous will go back when the water is down and will collect more. Meanwhile we used what we had to make the pigment for the faience and smelt in a crucible. Since we had so little, we saved it for the evening of the closing ceremonies. People were impressed with the bright blue flames.

Chris, of Maunfactum Historicum carved limestone moulds for us to cast in, making replicas of knives and daggers that were excavated in the vicinity. He also carved an impressive Egyptian kopesh. We didn’t get that cast, but will try for next year. We wondered about the limestone because we’d always been told that it wouldn’t work. However the moulds we’d seen were local limestone, and we found that this worked very well. Apparently not all limestone is created equal.

The above photo is a replica of a dagger we saw at the Museum of Archaeology and Nature, Gurzelyurt ( Morphou) in its limestone mould. We’ve also cast daggers that are replicas of one that was found here at Vounous.

I wrote a short article for EXARC about last year’s Vounous Symposium. You can read it here.

Crafting in the World: Materiality in the Making

Crafting in the World is a new work that combines the world of archaeology, craft, and anthropology. It explores crafts in ancient and modern contexts and discuses the relevancy of understanding crafts to other disciplines.

I had the privilege of writing one of the chapters for this book. In it I discuss how metal objects can be read in a way that the actions of the smith can be visualised.

"This volume expands understandings of crafting practices, which in the past was the major relational interaction between the social agency of materials, technology, and people, in co-creating an emergent ever-changing world. The chapters discuss different ways that crafting in the present is useful in understanding crafting experiences and methods in the past, including experiments to reproduce ancient excavated objects, historical accounts of crafting methods and experiences, craft revivals, and teaching historical crafts at museums and schools. Crafting in the World is unique in the diversity of its theoretical and multidisciplinary approaches to researching crafting, not just as a set of techniques for producing functional objects, but as social practices and technical choices embodying cultural ideas, knowledge, and multiple interwoven social networks. Crafting expresses and constitutes mental schemas, identities, ideologies, and cultures. The multiple meanings and significances of crafting are explored from a great variety of disciplinary perspectives, including anthropology, archaeology, sociology, education, psychology, women’s studies, and ethnic studies. This book provides a deep temporal range and a global geographical scope, with case studies ranging from Europe, Africa, and Asia to the Americas and a global internet website for selling home crafted items."

The link to the publisher is here. It is an academic publisher, and so it is rather expensive. However some university libraries already have copies, so I would recommend seeing if your local library can get a copy, or borrow it on Inter-Library Loan. If all else fails, contact me through the website or Academia.edu for a PDF.

Return to the Bronzezeitehof

Last year the Bronze Casting Festival was a wonderful experience. People from all over Europe came and exchanged information about bronze casting and metalworking techniques.

Here are a few photos of the First Bronze Casting Festival in 2017.

I’ll be returning there again this May and furthering my experiments in metal finishing. In addition to casting, I’m interested in using metal oxides as colorants for enamels and how they are affected by the reduced environment of a charcoal furnace. In the past I did a lot of metal enamelling in an electric furnace. This will be a chance to explore how the process of enamelling could have been developed. I might even have a chance to make some glass while I’m at it!

Forging Ahead!

January 2023

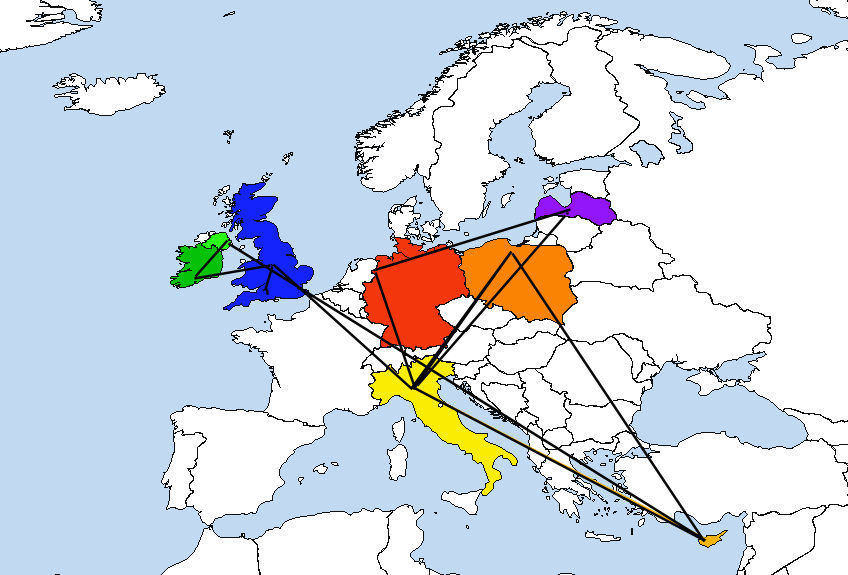

It looks like a crazy year of travel!

The year got off to a rocky start with me getting Covid while on a trip to Los Angeles. I’ve recovered and have a couple of months before I start the year’s journeys, and I am excited. It looks as if I’ll be busier than last year!

At the end of March I fly to Italy, where I’ll have a week in Modena to pick up my summer clothes and then fly to Northern Cyprus. I will spend the whole month of April there. The plan is to relax and see the country in the spring, but there’s a chance that I’ll be able to do some metalwork and give some lectures.

In May I head to Poland for the EXARC/EAC conference on experimental archaeology. Then it’s back to Italy to spend time with the family there, but at the end of the month I’ll head north to Germany for the Bronze Casting Festival, immediately followed by a trip to Latvia, where I’ve been asked to speak at a conference there.

Later in June, I’ll be in England for a couple of months where I hope to make some museum visits, help out with some workshops, and catch up with friends. In August I plan to go to Ireland and then head up to Belfast for the EAA Conference, where I’m co-chairing a session on experimental archaeology. From there, I head back to Northern Cyprus for the Vounous Symposium. I’ll spend a little more time in Italy before heading back to the US in the autumn.

Some of these workshops and travel expenses are covered by grants, but a lot of it is out of pocket for me. One of my sources of income is my Patreon Campaign. If you would like to support my work in experimental archaeology, please consider making a small monthly donation at https://www.patreon.com/archaeology Even a couple of dollars/euros/pounds a month really does help. Think of it as buying me a glass of wine after I’ve finished a day at a conference! Supporters do get benefits including postcards sent from all the places that I visit, early access to my podcast, In Small Things Considered, and special access to articles and publications that are exclusive to Patreon patrons. Special thanks go to those who support me on Patreon. You definitely are part of the excitement and fun of doing experimental archaeology!

2022 The Year in Archaeology and Conferences

2022 was an exciting year, full of archaeology, travel and travel mishaps, and exploring a world that had been closed off for two years.

In February, I finally got to work on the fellowship that was awarded to me through Historic Williamsburg and EXARC. I lived for a month in a cottage on the edge of the historic city and helped convert a jeweller’s lathe into a lapidary machine. For the final week, I was on display cutting gems in period costume, which was actually pretty comfortable. I wrote about the experience in an article for the EXARC Journal.

The year really got into gear in the spring when I landed in England and went to the Second Accidental and Experimental Archaeometallurgy Conference at the Ancient Technology Centre in Cranbourne. After two years of pandemic isolation in the US it was wonderful to be able to work with colleagues again. Before getting down to work, Fergus Milton took me over to Butser Ancient Farm to check out the new buildings. The site now has houses that range from the Mesolithic to Early Medieval and even includes a posh Roman house. Fergus is building his own dedicated metals workshop. I hope that I will get a chance to go down there and visit it when it is completed next summer.

The Archaeometallurgy conference was a great time. We constructed furnaces, laughed and joked, and shared information and stories about our respective fields of research. There were talks and presentations, a hog roast, and storytelling. Bronze was poured, iron smelted, and brass created. On Sunday the public came by to see the pyrotechnic action. They weren’t disappointed. I ended up spending more time talking to the public and explaining the event than actually working metal. That was a theme that continued through the summer.

In the end our furnaces were all destroyed and returned to the earth. By the time we left, there was little evidence that so much activity had been going on. To read more about it, here’s a link to my report in the EXARC Journal

I had a wild ride back up north with Ellie Blakelock and Vanessa Castagnino, laughing and talking the whole way. It was great to be in Sheffield again and going out into the Peak District with Gill and Ken. We checked for witches’ marks in the Tideswell Church, visited Bishop’s House, and I wandered around my old neighbourhood in Crookes.

I even got a little bit of excavating in at Castleton.

We also made a trip down to Derbyshire to visit Calke Abbey. It has one of the few remaining 19th Century faceting machines. After my experience at Williamsburg, I was interested in seeing one of these in the flesh. Calke Abbey is an experience in itself. It’s an old manor house that was donated to the National Trust, who have kept everything in situ. Everything is in a jumble, and only the library seems to have been sorted out. The director moved the machine out where I could photograph every inch of it, while Gill wrote down measurements. We did get to see more of the place, although we never got to the upstairs. As it was, there was more taxidermy than many natural history museums, and the family seemed to have a particular interest in lapidary and rock collecting. The curator in my sorely wanted to sort things out and label them, but the place is just as the last residents left it with doll houses, tiger rugs, and even a palanquin chair. It’s truly a place of sensory overload. I just wished that we could have sat ourselves down in one of the comfy library chairs and pulled out a book. A cup of tea would also have been a lovely addition.

In July I headed south and helped out with the Sedgeford Archaeological metals course, run by Ellie Blakelock. The Sedgeford Historical and Archaeological Research Project (SHARP https://www.sharp.org.uk/ ) is a long term excavation and field school. In addition to excavating an entire medieval village, they run basic and specialist archaeology courses. Despite the unprecedented heat, we had a great time building a furnace, carving moulds, and casting. The final day was an open day so the public got to see the students in action. The students had a great time and cast a lot of jewellery and small objects while learning the basics of primitive casting techniques.

The summer heat took Britain by surprise. I got a ride to the Kings Lynn Train Station. I had tickets to go from there to London and then catch the Eurostar the next morning and get back to Italy. The heat was so extreme that the tracks buckled, meaning that no trains could get in or out of Kings Lynn. After waiting a few hours I was lucky to hitch a ride with a young woman whose dad gave us a ride to Ely, where we could get the next train to London. I got a decent night’s sleep at the hotel I booked and then was up at the crack of dawn to catch the first Eurostar back to the continent.

I had a great time relaxing in Modena. I spent a lot of time at the local library taking advantage of the wifi and air conditioning. I visited friends in Siena where we visited as many museums as we could pack into a weekend. I also had some great evenings knitting with friends and making squares for the Viva Vittoria Project. In February 2023 we plan to cover the Piazza Grande with an enormous blanket, all to raise awareness about violence against women.

There was a bit too much adventure at the beginning of August when I tried to get to the Bronze Casting Festival in Uelsen in northern Germany. The plan was to take the train up near Karlsruhe, meet Kevin Frank and then we’d drive the rest of the way. Except… a couple days before we were due to leave, Kevin came down with covid. I had to figure out how to get up there by train, starting from Karlsruhe. It was the high point for holiday travel in Europe, and Germany was offering 9 euro tickets to promote public transit. The trains were packed, and always running late. I missed so many connections and kept having to cobble together a new route and schedule at every station, straining my limited German language skills. It took almost exactly 24 hours, but I got there finally. I was exhausted and then found out that other participants had cancelled out due to Covid or other issues. That left me and Matthias Fischer to get things up and running, teach, and then demonstrate to the public on Sunday. The event was only a weekend, rather than a full week, so there was little time to get my brain together. But it was good to be back, and I enjoyed the event and seeing everyone after so long.

Then I faced the trip back down south. Knowing that it would still be insane, I arranged to spend the night at Kira and Tony’s place in Köln. What should have been an early evening arrival turned into me rolling in around 11 pm. Instead of sleeping, like any sane person would, we stayed up talking and drinking wine all night. I did get a little nap in before heading back to the station. I got there on time, only to find that the first train of the morning train was delayed. The trip back had about as many delays and rescheduling as the trip up. I was so glad to be back to Italy where, despite so many complaints, the trains do tend to run on time, or at least better than they do in Germany.

At the beginning of September I flew to Budapest to speak at the EAA (European Association of Archaeologists) conference. My paper was on examining the industrial waste from primitive non-ferrous metalworking, both in ancient and modern experimental contexts. I’m hoping to continue this project and have started to look for resources and ways to support the project. Meanwhile Budapest was beautiful. I only saw a small portion of the city, and spent most of one day at the museum. I definitely have to go back again.

Then it was back to Modena briefly. I had enough time to wash my clothes and repack my bags. Then I was off to North Cyprus for the Vounous Symposium.

My goal for this year was to replicate a set of pot bellows that were excavated at Enkomi, a Bronze Age site near Famagusta. Kevin was still out with covid and Chris couldn’t afford to come, so I was on my own again. Except that Vounous is a huge supportive community. I met Ergün Arda, a ceramic artist from Turkey who took time away from his work to make the bodies for the bellows. A ride was organized so I could go to the leather supplier to get the hides I needed for the tops of the bellows. Then we had a tense night hoping that the bellows wouldn’t crack during the firing. They turned out perfectly and everyone was fascinated by them. In the following days anyone who wanted to had the chance to use them. Again, I didn’t get much in the way of casting or smelting done, but together we made an important piece of equipment that is closely related to the heritage of the site. During the symposium I finally started the Turkish language course that I’d been trying to get on for over a year. I dearly hope that I will be able to speak Turkish reasonably well by the time I return.

I always hate to leave Vounous, but at least I was heading back to Modena. It’s a good place to relax and recharge. I got to spend some time with my cousin Paolo and enjoy the cooler weather. Then in early October I headed back north to Germany to Adventon, a medieval/Viking era open air archaeological park http://mittelalterpark.de/. Kevin has been building a metals workshop there, and originally he planned for an event to celebrate the completion of the workshop. Instead, a small group of us finished putting on the roof and getting most of the walls done. Even if we didn’t get any metalworking done, it was still a great time. The weather was good for the most part, and we had a great time drinking Turkish coffee, talking, and eating meals together.

At the end of Adventon, I had to return to the US. My allotted three months in the EU were up. Unfortunately, my late afternoon flight was changed to an early morning one, meaning I had to beg a ride from Kevin, and we had to get up at 4 am to get me to the airport on time. That was not appreciated by either of us.

Back in the US, I have been finishing up a lot of projects that have languished. Knives have handles now, and I finished a sickle that was a commissioned piece. I’m at the lathe as much as possible, and I’ve also joined a foundry where I can get casting done over the winter. I have some very cool projects in mind and a lot to do in the three months until I leave for Europe again at the end of March.

Next year is already filling up. I submitted an abstract for the EAC conference in Poland in April, and the EAA in Belfast in August. There’s the Bronze casting Festival and Adventon, and of course Vounous. Speaking of which, I’ve only been in Northern Cyprus in September and very much want to see it in the spring when it is green. I’m making plans to be there in April and maybe got some metalworking done while I’m there.

2022 was an exhausting year of missed connections and difficult travel, but it was all so worth it. After the two years of pandemic lockdown, seeing so many friends and people I love, being able to work again and teach, pour metal, all of that was the greatest gift I could have asked for. Here’s to 2023 and all the adventure, but maybe with better travel connections.

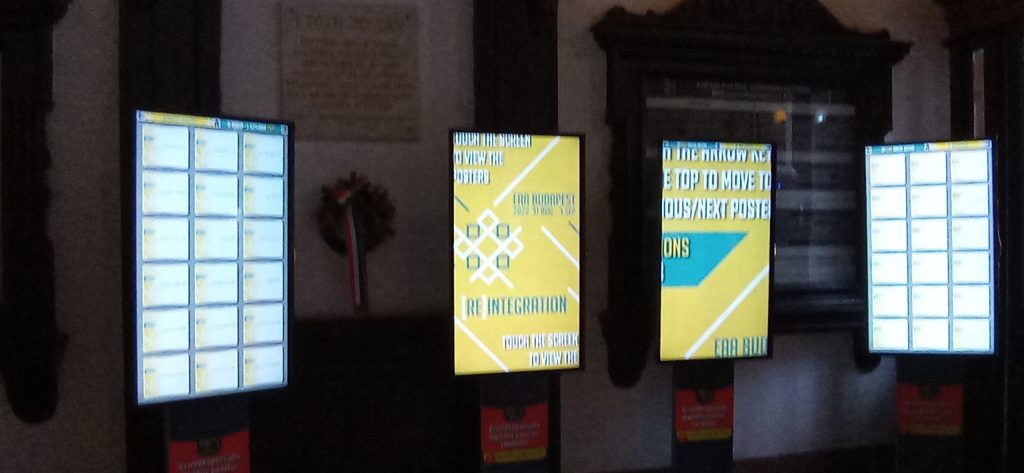

September 2022

I’m back from the conference of the European Association of Archaeologists in Budapest. There were a lot of great sessions, and as always it’s impossible to see more than a fraction of what’s going on. This year the conference was a hybrid of in-person presentations and virtual. Every session had participants who joined in online. The sessions I attended went seamlessly, although it must have been tough for people on the west coast of the US who were giving their talks at 5 am Pacific Time. The poster sessions were also virtual. There were no printed posters. Instead touchscreens allowed viewers to select a session and see the posters. All of these innovations allowed for people to participate who would normally be unable to attend the conference. However, there were some people who I wish would have been able to make it, if only to have in person conversations. Still, the conference was inspiring and I came away with fresh ideas and seriously thinking about new projects.

Budapest is beautiful and the National Museum there is world class. The displays and layout are outstanding. Many of them allow the visitor to walk around the object, or at least to be able to see them from more than just one angle. The objects themselves are truly worthy of the treatment they get. I spent an entire afternoon there and would willingly go again and spend more time.

But there’s no rest this week. I arrived back on Saturday and tomorrow, the 6th I fly out to North Cyprus for the Vounous Symposium. There will be two weeks of smelting copper and melting bronze, and maybe we’ll get back into making some faience.

July 2022

The year continues, although the excessive heat has been a bit much, especially when working with hot metal!

The Accidental and Experimental Archaeometallurgy 2.1 Conference was a blast. It was great connecting with everyone again and getting some work done. Thanks to Vanessa Castignino who went all out to make the event a success. There was the usual friendly rivalry between the ferrous and non-ferrous people, with furnaces of all shapes and sizes. There will be a short review of the conference in the EXARC Newsletter, coming out soon.

After a relaxing time in Sheffield, where I actually got to do a few minutes of excavating, I headed down to Norfolk for Sedgeford’s Archaometallurgy day course. We had some great students and built a permanent bowl furnace, so we don’t have to start from scratch every year. We did try to smelt copper, but ironically the weather was too hot to continue bellowing, so we just couldn’t get the furnace hot enough without roasting the people pumping the bellows.

Right now I’m in Modena, Italy where the extreme temperatures continue. However, I am looking forward to a cool time in Uelsen, Germany where I’ll be at the Bronze Casting Festival. I plan to continue my experiments with self-draughting furnaces, and use my 3D printed pins as forms for some sand casting.

Later in August I’ll be presenting at the EAA Conference in Budapest, and then I just got word that the Vounous Symposium will be back for another year! I am so looking forward to seeing everyone in North Cyprus again. Last time we started making faience for the fun of it. Who knows what we’ll try this time, in addition to all the usual smelting and casting…

************************************************************************

2022 is finally picking up where 2020 left off. I’m back in England and this weekend I’ll be at the Historical Metallurgy Society’s Accidental and Experimental Archaeometallurgy 2.1 Conference. Next month I’ll be at Sedgeford for SHARP’s Metallurgy day course. Then in August, I’ll head up to Uelsen, Germany for the Bronze Casting Festival at the Bronzezeithof. At the end of August I’ll be speaking at the EAA Conference in Budapest. Plans are still afoot for heading down to North Cyprus in September, although I haven’t had official word about another Vounous Symposium. Fingers crossed, though. It’s an exciting event and one where we have two weeks to work rather than just a weekend.

It feels great to be on the road again, although hauling a suitcase full of bronze tools can get a bit tiring at times. Still, I wouldn’t trade this life for anything!

Welcome to 2022 and Some Resolutions

Last year, in 2021 everything was cancelled… again. The world was put on hold for another year. We all got tired of waiting for the next shoe to drop, not realizing that it was a centipede that was dropping them. It was as if the promise we hoped for in 2020 was snatched away. Some people reacted with anger, but for me it was withdrawal. I checked out for a while. When I look back on all the stuff I did last year, it looks like I was insanely busy, but to me it felt as if I had been treading water, waiting for life to come back to some form of normal and leave the US behind. Still, hope springs eternal. My fellowship at Colonial Williamsburg that’s been delayed three times is rescheduled to happen next April and with luck I’ll be back in Europe this summer.

I did get a furnace built last year. It’s self-draughting, so I didn’t even need a set of bellows. That was convenient and a real labour saver, but it brought home how much bronze casting is a communal event for me. I missed the camaraderie, the laughing, storytelling, and the intensity of working as a close-knit team. I never bought into the idea of the lone, itinerant Bronze Age metalsmith, unbound from the structure of society. As a metalsmith, I am pretty itinerant, but I am rarely alone, and there is always some sort of social structure. In the modern world it is much easier to do this sort of work alone, but that is essentially an illusion. I head over to the hardware store and buy bags of charcoal and order bags of clay to be delivered here, but in the Broze Age there would have been a lot more interaction to get the necessary supplies. If the people who dug the clay and burned the charcoal weren’t a part of my village or settlement, I would have had to negotiate how to get the supplies to where I was working. Likewise for the metal or ore. The Bronze Age was a world without a lot of easy transportation. Something we take for granted now.

These days it’s unfashionable to do New Year’s resolutions. People point out that there really isn’t anything special about the transition from December 31st to January 1st, it’s just an arbitrary date. It is an arbitrary date, but it’s also a long-standing tradition and there is a certain amount of power in traditions. 2021 was certainly a depressing year. Then New Year’s came and went. Compared to New Year’s Eve in Italy and England, there’s not much going on here even in a non-Covid year. It was a low point for me, and it came to the point where the only way was back up again. So, I did make resolutions. Small ones that will get bigger as I get back into the swing of things. It felt right. I feel as if I am getting back into the game and even if I don’t have a lot of energy, I’m acting as if I do. In the coming weeks I plan to put up a page of bronze casting moulds, similar to the page I made for textile tools. I’ll also write a full report on my self-draughting furnace, that amazingly seems to be holding up in the sub-zero weather here, and I’ll polish up and publish some old articles of mine. So, I’m back and hoping to make up for lost time.

Now we’re Cooking with Gas! How experimental archaeology challenges modern assumptions about metal recycling.

New article available through EXARC. See the link below for the full article

It is accepted knowledge that when re-melting alloys, some of the metal with a lower melting temperature is lost through oxidation, and more metal must be added in order to maintain the desired alloy proportions. In order to understand the changes in alloy content when recycling using Bronze Age technology, experiments were undertaken by the author and others, using a charcoal furnace. These experiments included recycling bronze to quantify the loss of tin, and how alloys were affected by co-melting metals. The results were then compared to modern metallurgical practices using electric and gas furnaces. The initial results were presented at the Historical Metallurgy Society’s Research in Progress Conference in November of 2009. However, this paper includes further experiments that build on the earlier work. The conclusions indicate that knowledge of earlier practices was lost with the advance of technology, and that broad assumptions cannot be made about earlier technological practice based on work done with modern equipment.

Read the full article here

Experimental Archaeology at Western Illinois University

On November 1-3, 2017 I was in Macomb, Illinois leading a bronze casting workshop at Western Illinois University. This was the first event of its kind for the University and few people there knew what to expect. While the archaeology program provides for a certain amount of flintknapping and some pottery done by students, there was no available program for the introduction of the method and theory behind experimental archaeology.

Professor Andrea Alveshere, a colleague of mine from the University of Minnesota and I discussed the possibility of my coming to give a short seminar and workshop. There wasn’t much in the way of funds for the project, so I agreed to come as long as my expenses and materials were covered. It was a program that both she and I very much wanted to introduce to the university.

I had a long train ride from St Paul to central Illinois, but enjoyed seeing the landscape. I arrived fairly late that evening and was taken to cabins on rural property now owned by the university. The land and cabins had been bequeathed to the university and they are a great resource. In addition to dorm-like cabins with bunk beds, bathrooms, and limited kitchen facilities, there is a dining hall with a complete kitchen. We made sure that there were supplies for coffee and breakfast and checked out the site where we would build the furnace.

The grounds around the cabin are level and grassy, and there was already a large firepit with picnic benches arranged around it. I met the site manager, and we chose a spot beyond the firepit where we could construct a small pit furnace. She was excited about the project and had no problems with holes being dug. She also liked the idea of the furnace being buried when we were done with it so that it could be excavated later.

We hit the ground running on Thursday. Andrea picked me up and we went to the university where I met students and staff in the art metals department. They were excited about participating in the project and were glad to provide us with supplies. The idea of primitive casting was fascinating to them and they looked forward to the event. I borrowed some tongs and other equipment from them, with more to be delivered the next day. While we spoke, one of the professors who teaches pottery came in. We needed clay, and I had to explain that we wanted his worst stuff, the stuff that’s scraped off tables that’s usually discarded or sent for recycling. He didn’t quite understand why we wanted the useless clay, but he said that we could have as much as we wanted.

After lunch we made a run into town for more supplies. We found bags of sand and proper lumpwood/natural charcoal at the local farm store for a reasonable price. The plan was to cast into cuttlefish bone since two days was not enough time to make moulds for lost wax casting. Andrea had ordered cuttlefish bone from a wholesaler, but unfortunately when the shipment of arrived it contained packages of aquarium gravel. So we were also scouring local pet stores for cuttlefish. Andrea contacted the company she ordered from and arranged an overnight delivery, but there were no promises that it would arrive in Macomb in time. The nearest FedEx office was in Peoria and it would have to go by post from there to Macomb.

We agreed to meet up at the site at 2:30 to build the furnace. When we arrived, a few students were already on site. I explained to them about clay mixing and the reasons we mix sand and dung with the clay. In the process they got a basic lesson about ceramic petrography, and early clay recipes.

By the time we were done they had a working knowledge of clay bodies and the physical experience of working with it as well. A hole was dug and then it was lined with clay. I explained about tuyeres and used a branch to construct a clay-lined hole that ran from the top edge to the base of the furnace. When I build a furnace I usually ask the students to decorate it in some way. Usually something is put above the hole where the tuyere comes in. While working, the students decided that the furnace should have a turtle head above the tuyere. A nice choice, since the glowing charcoal would make for an interesting turtle shell! While they worked on that, I made the platform (also known as teapot stands or perforated clay slabs) to place in the furnace. By 6:30 pm we had everything done. That was right on time since I needed to change clothes for my talks at 7 pm at the university.

Once I was cleaned up Andrea took me to the lecture hall. It was a great facility with a large wall-sized screen and auditorium seating. It was almost half full, which was good considering that it was a weekday evening and the subject was unfamiliar to most people. Despite that we drew attendance from the anthropology and art departments, in addition to members of the local archaeology society and members of the public who were not associated with the university.

I gave three short talks in succession with questions and answers after each one. These were all presentations that I’d previously given at conferences, all of which were about 15 minutes long. I started off with the one I gave in Oslo about the significance of mistakes and how they are preserved in metalwork. The second was about Minimum Tools Required, a portion of my PhD thesis that organised the chaîne opératoire of metalworking. The final talk was about excavating metal, based on the BAJR guide that I’d written. The questions were enthusiastic and despite there being little in the way of prehistoric metal in the region, there was interest in the subject. I did answer a couple questions about Lake Superior copper use among Native Americans. There is some debate as to how some of the copper objects arrived in central Illinois from northern Minnesota. Were finished objects traded by Native Americans, was the raw material transported and traded, or was the copper a chance find of raw material that had been redeposited in southern Illinois by glacial action? I hadn’t seen the objects, but typology might provide a part of the answer. At the end I spoke a little about what we would be doing the next day.

Afterwards Andrea and I returned to the furnace. Although it was still damp, I wanted to get it dry before casting the next day. We laid a little fire and sat talking late into the night. The presentation had been a great success and it looks as if it generated a lot of interest.

Friday I was scheduled to give a talk on experimental archaeology at noon. This was basically an introductory lecture about why and how experimental archaeology is done, along with the basic ground rules for doing experimental work. Word had gotten out and the room was filled to capacity. After the talk we headed back to the site and got to work. Because we hurried the process along last night there were a couple cracks in the furnace, but because it was set into the ground the cracks had little effect. The furnace was still warm from the previous night and I used a trusty pig scapula to scrape out the ash and leftover charcoal and then fit the platform in place. The fire was lit and after I had worked the bag bellows for a bit, the students took over. Every group I work with seems to have a different approach as to how to operate the bellows. I know that the way I do it, alternating pumps with one per hand, is difficult to coordinate for many people trying it the first time. Some people never quite get it and just pump both the bellows at the same time (affectionately known as the Cambridge Method). Here, the students teamed up and had one person per side, operating the bellows with both hands. They were surprisingly well-coordinated. The students were energetic and worked long sessions without tiring. At times I had to ask someone to give up their place to let another student try. I wanted to make sure that everyone who wanted to (including non-students who had come to see what was going on) had a chance at the bellows. The furnace took a bit longer to get the first crucible of metal melted than it normally does because of the frequent changes of personnel pumping the bellows, but we did get there. About an hour after we started Andrea got the call that the cuttlebone had arrived. Students were already carving moulds from what we had on hand. Now things were in full swing. I was grateful to the jewellery professor who took on showing the students how to prepare and carve the cuttlebone while I supervised the melts.

There were a few failures due to improper mould preparation. It gave me the opportunity to explain how easy it was to lose droplets of metal while casting and pointed out the debris that was getting trampled around the furnace, tell-tale clues that an archaeologist needs to look out for in a site that could be mistaken for a cooking pit. Every experience that day was a teaching moment. Both instructional and non-discursive. Repeatedly students told me that they had never known that there was such a thing as experimental archaeology, and that they were thinking about archaeology in a new way. A couple students who had not yet declared were suddenly thinking about the possibilities of having a major in anthropology.

The students wanted to keep going despite a large pot-luck dinner that had been prepared, so we all went to eat in shifts. When I took a break, people assured me that I wasn’t too soot covered, although I felt as if I had charcoal smoke in every pore. The head of the Anthropology Department came up and complemented me on my lecture. He was impressed by how I presented the information and noted the enthusiasm of the students. The potluck was also attended by members of the local archaeology society who aren’t formally a part of the university, but attend functions and often work with students on projects. We had a great time talking about local archaeology and experimental work.

After dinner we worked a little more, but it was long past the time that we could see well in the dark. We packed up as much as we could find and put it all in the cabin.

I had the choice of leaving on Saturday or Sunday. I opted for Sunday because the train left at 7 am and I knew that Friday would be a late night. I told the students that if they were interested, we could continue casting on Saturday. I had no lectures or other plans, so we agreed on a 10 am start.

The next morning we had another good-sized group of students. The previous day there had been close to a couple dozen people in the afternoon and rarely fewer than a dozen visiting throughout the day and evening. Saturday was more relaxed, but still well-attended. Students made moulds and instructed new participants who hadn’t been there the day before. The more experienced ones were already taking on tasks like they were old hands at it.

Andrea was amused that this was supposed to be my day off, but instead it was another full day of casting. Some experimentation was done with hammering (using my bronze hammer and anvil) and other finishing work. One student was keen on textile archaeology, so she cast some beautiful spindle whorls. I also made some clay ones with her, using some of the scraps left over from building the furnace. Once dry, she’ll take them to the art department to see if she can get them fired there. I heard that they also do raku pit firing.

Towards evening I needed to call it quits. I had an early start in the morning and needed to get things cleaned up and packed. The students reluctantly poured the last moulds and we got everything in order. The next day they would cover the turtle furnace with dirt and let it deteriorate. Left to itself, it should be covered in grass in a year. In a year or two it will be just as useful as a teaching tool for excavation.

The entire event was successful and exceeded our expectations. We had brought an entire new perspective on archaeology to the department, and the department heads were impressed. In my talk I had emphasised the value of programs like this not only for hands-on student learning, but also as a unique opportunity for public interaction with the department. Too often universities are segregated from the surrounding community leading to the local residents wondering what goes on there. Experimental archaeology programs, especially those performed out of doors, provide an opportunity for interaction and public participation, and even drawing on experience of people from outside the university. Andrea and I discussed the possibility of doing a longer workshop or even the possibility of an accredited short course. Now that the department has been given an idea of what can be accomplished, they might be more amenable to funding it.

These are ambitious ideas in a time when universities are hurting for money. I was glad to be a part of this mainly because I wanted to help Andrea introduce experimental archaeology to her students and colleagues. There was no budget for such an unknown project, but because we were keen on this, Andrea scraped what funds she could get at short notice and we put it together on a shoestring. I would love to pursue this and give students the full range of what an experimental archaeology course could offer, but that is for the university board to decide.

In the meantime, I would like to thank all the people who support my project on Patreon. They provided the opportunity for this seed to get planted and for students to have a unique experience that will benefit them in their careers as archaeologists. The contributions made through Patreon and PayPal go towards giving more people the opportunity to explore the world of material culture in a way they never realised before. If you’re interested in finding out more about my Patreon project or making a sustaining contribution please click on the link below.

|

Did you find this information useful? Please consider supporting this site with a small donation through PayPal |

Nobody’s Perfect: Contrasts in Craft session at the Nordic Bronze Age Symposium

June 2017

It was my pleasure to present a paper at the Nordic Bronze Age Symposium in Oslo . The conference focused on contrasts and connections in the Bronze Age. Presenters covered a wide range of topics from landscape, technology, social practices and materialities.

The session that I participated in was titled Nobody is Perfect: Contrasts in Craft. I spoke about recognising the learning process by examining mistakes in metalwork. It was a great session and I hope that the research presented here will spur others to examine the flaws in objects to understand the processes of craft production.

Too often artefacts are selected for examination and display because of their perfection, but perfection can limit us. We see the end product but by the very process of achieving perfection the traces of the journey to mastery are erased. When we examine flaws, both minor and major, the world opens up.We can follow the movements of the artisan’s hands and see the sequence in which an object was made. We can see the choices made during production. Was there a flawed section of decoration because a master artisan was momentarily distracted, or was it because an apprentice was still awkward using tools? We can also question why the flaws remain; why the object survives, rather than having been destroyed or repaired.

The flaws, repairs, and mistakes all contribute to the object’s biography and allow us a glimpse of craft and decoration in ancient cultures. The papers presented in this session examined these and more subjects on mistakes in craft, and generated lively discussion.

“Nobody is perfect: contrasts in craft – for the first time at an archaeological conference artists, craftspeople and archaeologists gathered together to discuss the potential of mistakes, failures and repair within material culture of the past. The results were stunning: mistakes, failures and repair can not only help to identify skill level and apprenticeship in craft, they also indicate the intention, the actual purpose of an artefact.” – Heide W. Nørgaard

The Mavis Furnace or how to build a furnace for almost no cost!

I was visiting my sister in the autumn of 2016. She has a bit of land just outside Albuquerque, New Mexico, so I asked her if I could build a furnace and do some casting there. I’ve built plenty of pit furnaces, so this time I wanted to build one that was above ground and a bit more visible. It would also mean that no one would trip and fall if they forgot where I put the thing.

The first task was to get the basic materials: Clay, Sand, and Horse Manure.

I thought that the clay would be the biggest hurdle. However my sister’s neighbour happened to be a sculptor who works in both iron and ceramics. She went to her regular clay supplier and got a couple feed sacks full of dried clay for free. Potters who work at wheels, or work with students end up with a lot of clay that is scraped off of workbenches and wheels that is hard to re-use. It often has a mixed consistency, it’s lumpy or part dried. If they want to use the clay again, it has to be reconditioned. So, they take their sacks of scrap back to the place where they buy the clay and pay to have it put through the mill. Since it’s not really usable, some potters are willing to just give it away. So thanks to Liz Fritzsche, who does amazing and beautiful work in porcelain, I was able to get started.

I threw some of the dried clay into a five gallon bucket and poured in enough water to cover the clay and let it sit. It was squishy and workable in a few hours. Next up was locating horse manure. A friend of a friend has horses, and they were grateful to have someone who would haul away a couple of barn buckets full of manure. The final bit was the sand. My sister did have some beach sand that she’d bought for the garden, but I was more fascinated by the soil there. Her land is in the old Rio Grande River Valley, and the soil is a mixture of silty sand and a little clay that had been pounded to a powder. The soil was almost the consistency of dust. It mixed in perfectly and later I found the mixture was highly resistant to cracking.

The ingredients were mixed with some water, stomped, and the proportions were adjusted until it was perfect. New Mexico is a lot drier than England, so I ended up adding more water than usual as I worked. It was also nice knowing that it was unlikely for any rain to fall while I was working.

The silt/clay/dung mixture made a durable clay, and after I flew back to Minneapolis, I was please that the crucibles and moulds I packed in my check-in luggage survived airport handling.

The furnace walls are about 8 cm wide (about the width of my palm) and the inside diameter is about 25 cm in diameter. I let it dry for a couple days and then moved it over to an unused area behind a greenhouse where I would have more room to work. I set a small fire with cottonwood branches, fed it for a couple hours, and then let it die out overnight.

We all like to put some decoration on our furnaces. My students have done everything from dragons to turtles to cats. I had been thinking about doing some decorations imitating the local petroglyphs, but as I was working it just seemed natural to do a portrait of Mavis, my sister’s exuberant German Shepherd.

Finally I adjusted the mix to have a bit more of the silty sand and horse dung to make the teapot stand and crucibles. For more information about teapot stands and how they work in furnaces, check out my article on the Umha Aois website here.

Later I added more water to make the slip for dipping waxes in for the first stages of mould making. The silt made a wonderfully fine mould that picked up all the details. Honestly, this mix was as good as jeweller’s investment for picking up detail.

I had some cracking on the upper part of the furnace, and noted that the part that cracked was where I used the commercial sand. The silty New Mexico soil held up much better. If it weren’t so heavy (and probably not allowed) I would have hauled bags of the soil on the plane home to use for more projects.

Both Mavises performed very well (Mavis the Dog is into barrel racing and advanced obedience classes). I’ll be interested to see how it holds up over the winter. Winters in New Mexico tend to be mild, so I’m hoping that the Mavis furnace will be available for friends in Albuquerque to use for some time to come.