Photo by Rauf Ersenal

I wanted to recreate one of the gold leaf crowns found in Cyprus. These date back to the Bronze Age there and have been found in burials. The one I chose to replicate is in the Güzelyurt Museum of Archaeological and Natural History, Northern Cyprus. The crown has ivy leaves, berries, and two tendrils.

The original was made of gold, however unable to afford that much gold, I used copper and gold leaf. I also did not create the wire or sheet from scratch. I had planned to make the berries using a dapping block, but a bout of Covid meant that I lost a couple of weeks of time to work on it, so instead I bought 8 mm copper beads.

Making the structure of the crown

The base of the crown was made from Copper Tube (5/32″ ID × 3/16″ OD(4-5mm)) that is commonly used for refrigerators. The original was made from two pieces that were overlapped and held together by wrapping with wire in two places at the back. Since I intended this to be worn, I wanted the crown to be as sturdy as possible, so used one piece of tubing. The original and the replica are both open at the front.

The first step was to drill holes in the tubing. Twenty-four leaves are concentrated along the sides and front. The leaves are in twelve pairs along each side.

The leaves were cut from 30-gauge (0.31mm) copper sheet. The metal was thin enough to be cut with a strong pair of scissors. Long stems were cut out extending from the leaves. The leaves were chased to imitate veins using a bronze hammer with a chisel shaped face. The stems were twisted and then were inserted into the holes and soldered in place.

The berries were put on stems by inserting 12-gauge (2.6mm) bronze wire into the bead and soldering at the top. The stems were then soldered in bunches. Tendrils were made of 18-gauge (1.2mm) wire and soldered into two of the clusters that would be placed at the front of the crown. Four clusters of berries were soldered to the front of the crown by inserting into drilled holes and the ends of the tubing. Two more clusters were inserted into holes along the sides, facing outward.

The soldering was at times frustrating. I would get several in place, and then a leaf halfway around the crown would fall off. I ended up soldering one or two leaves and then leaving it for a half an hour to cool down completely before continuing to add leaves.

Applying the gold leaf

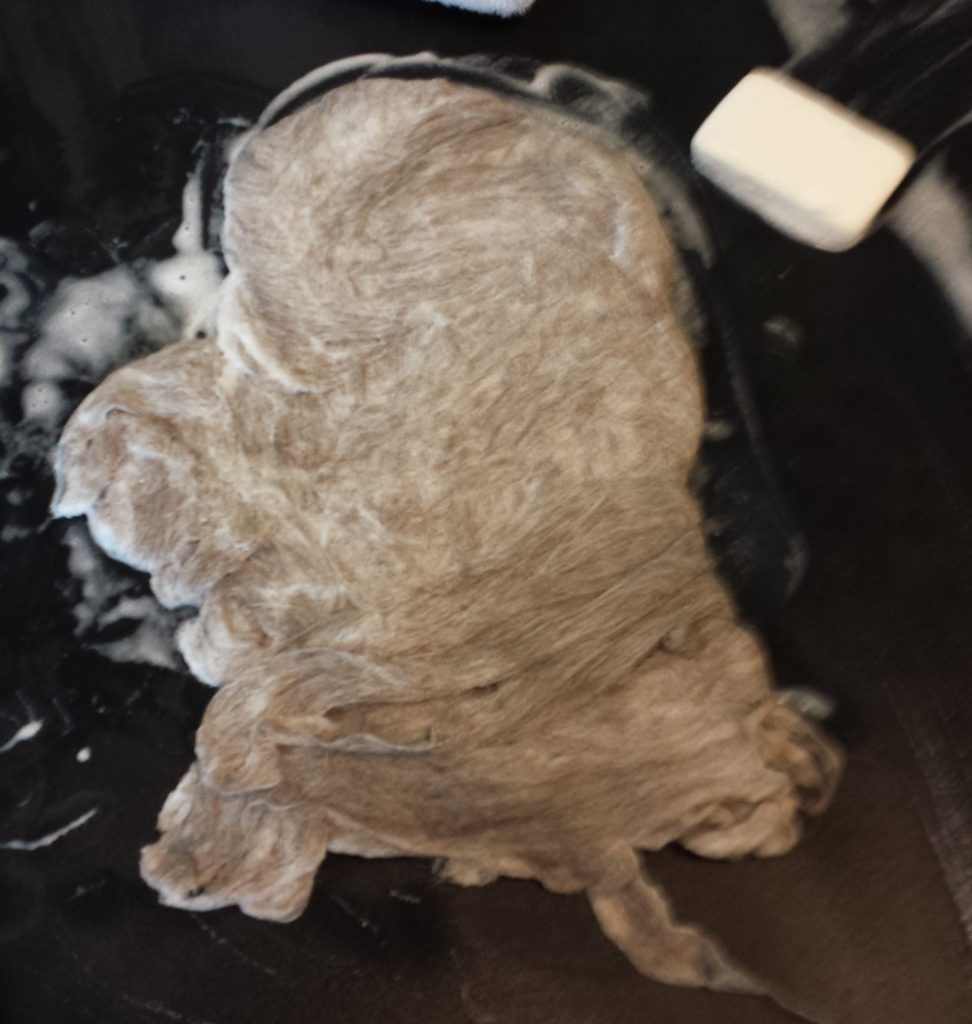

Leaves were coated with thinned PVA glue and gold leaf applied directly using fine sable brushes and tweezers. One was used for applying the glue, while the other was kept dry to to smooth the gold leaf. Multiple layers were applied, with each layer coated with the thinned PVA glue and allowing to dry. Despite the layers, the chased details were still evident.

Transport

The crown was to be packed into my carry-on bag for the flight to Italy and then Cyprus. For that I needed to make a sturdy box and interior supports. A box and lid were constructed of carboard and hot glue. Inside, supports were made of bubble wrap and closed cell foam. Supports were placed in the four corners and the centre, so that the crown would not shift during transport. The interior was lined with crumpled Tyvek®. Tyvek® creates a smooth snag free, inert surface that is ideal for contact with delicate metal surfaces. The interior structure was fixed in place using hot glue.

Despite my worries, airport security and customs did not notice the crown and it arrived safely. It was presented to Şenol Özdeverim, Rauf Ersenal, and Celal Dimililer during a meeting at the Çatalköy Belediye. The crown will be worn at the opening ceremonies of the 5th Annual Vounous Symposium in September 2023.

Photo by Rauf Ersenal